Huatal HBW counter flow closed cooling tower

Release date:

2020-08-06

With the development of industrial manufacturing, closed cooling tower is more and more used in industrial cooling, closed cooling tower has counter flow type, cross flow type and hybrid flow type, three categories. Today we would like to share with you about our classic HBW counter flow closed cooling tower.

Industrial application of cross flow closed cooling tower

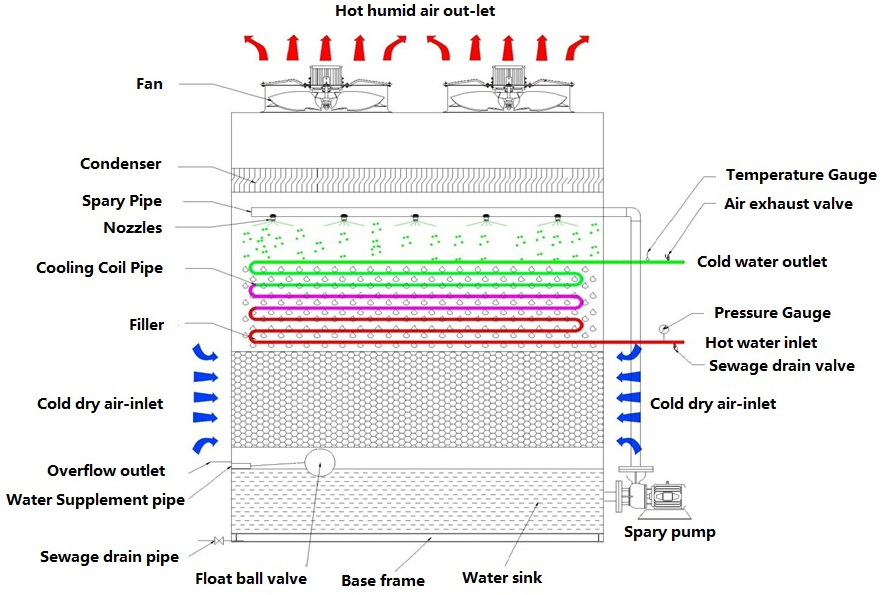

Operation principle of HBW counter flow closed cooling tower: the working fluid (pure water or other liquid) circulates in the coil pipes of the closed cooling tower, and the heat of the working fluid radiates into the water spraied on the coil pipe. At the same time, the cold dry air outside enters the unit from the inlet grille on the side, intersects with the flow direction of water, and flows through the coil pipe in reverse. Small part of the water evaporates and absorbs the heat. The hot and humid air is discharged into the atmosphere by the fan on the top of the cooling tower. The rest of the water falls into the bottom water basin and recirculated by the pump, and then spraied onto the coil after pre-cooled by the fills.

HBW counter flow closed cooling tower characteristics:

Adopts imported magnesium aluminum zinc alloy plating steel sheets as cooling tower's outer shell, has outstanding anti-corrosion effect, and its service life is 10-20 times over galvanized plate. The coating on the surface has fluidity and notch protection (self-healing);

Counter flow cooling, less heat dissipation blind area, high heat exchange efficiency;

High efficiency water condenser, During operation, water drift rate ≤0.001%;

The coil pipes adopt anti-freeze, energy-saving design to ensure the circulation water can be completely drained to avoid freezing damage when the air temperature is low in the northern regions;

The unit design is elegant, automatic digital display, easy to operate and maintain;

Our HBW type counter flow closed cooling tower has been used and affirmed by thousands of customers for ten years since it was launched on the market, and its efficient maintenance method has won praise from customers. We have always been committed to solving problems and creating value for our customers. In the process of continuous development, we have been providing the best closed system solutions for our selected customers.