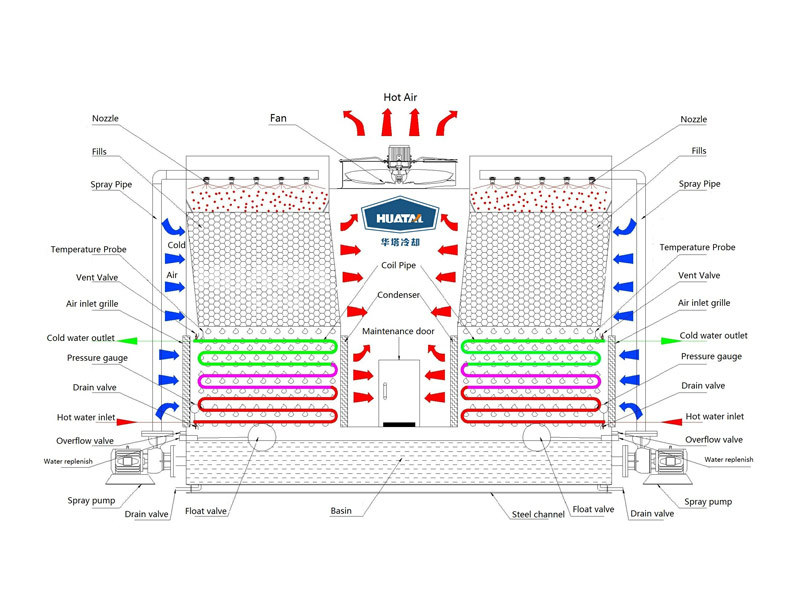

HBY Cross Flow Closed Cooling Tower

Imported POSCO Zinc Magnesium Aluminum Alloy Coated Plate with outstanding anti-corrosion effect. The service life is around 10-20 times of normal galvanized plate, the surface coating has fluidity, with cut protection (automatic healing).

Category:

Keywords:

Product description

·Imported POSCO Zinc Magnesium Aluminum Alloy Coated Plate with outstanding anti-corrosion effect. The service life is around 10-20 times of normal galvanized plate, the surface coating has fluidity, with cut protection (automatic healing).

·Water sprays on the surface of condenser to avoid water scale in the dry point area, thus maximizing the efficiency of the system.

·The effective dehydrator features extremely low drifting ratio.

·Small occupation, set with inspection gallery for daily maintenance.

·It is the anti-freezing and energy saving cooling tower. When we shut down the system, the water in the condenser can automatically return to the water tank for protecting the condenser from freezing. The system also has automatic digital temperature display and control, energy saving and eco-friendly.

|

HBY series coil pipe minimum water flow chart |

|

|

Type |

(Liters/per sec) |

|

HBY-19A、19B、19C、19D、19E、19F |

6.9-18.1 |

|

HBY-22A、22B、22C、22D、22E、22F、22G |

22.2-48.6 |

|

HBY-26A、26B |

55.6-62.5 |

|

HBY-29A、29B、29C |

69.4-83.3 |

Technical parameters

|

Type |

Finished Size (mm) |

Pneumatic system |

Spray pump |

interface pipe diameter (mm) |

Weight |

||||||||

|

Tota length (L) |

Length (L1) |

Width (W) |

Height (H) |

Power (kw) |

Air volume m3/h |

Power (kw) |

Water yield m3/h |

Inlet and outlet pipe |

Overflow outlet sewage outlet |

supplement water pipe |

Net weight (Kg) |

operating weight (Kg) |

|

|

HBY-19A |

2540 |

2180 |

1940 |

2200 |

1.1*2 |

26000 |

1.5 |

45 |

DN80 |

DN40 |

DN25 |

1020 |

1820 |

|

HBY-19B |

2960 |

2600 |

1940 |

2200 |

1.1*2 |

26000 |

1.5 |

45 |

DN80 |

DN40 |

DN25 |

1050 |

2020 |

|

HBY-19C |

2960 |

2600 |

1940 |

2200 |

1.1*2 |

26000 |

1.5 |

45 |

DN80 |

DN40 |

DN25 |

1100 |

2100 |

|

HBY-19D |

3360 |

3000 |

1940 |

2200 |

1.1*3 |

39000 |

2.2 |

60 |

DN80 |

DN40 |

DN25 |

1310 |

2540 |

|

HBY-19E |

3360 |

3000 |

1940 |

2580 |

1.1*3 |

39000 |

2.2 |

60 |

DN100 |

DN40 |

DN25 |

1450 |

3080 |

|

HBY-19F |

3360 |

3000 |

1940 |

2730 |

1.5*3 |

54600 |

2.2 |

60 |

DN100 |

DN40 |

DN25 |

1520 |

3200 |

|

HBY-22A |

4220 |

3800 |

2240 |

2680 |

1.5*4 |

72800 |

2.2 |

114 |

DN125 |

DN40 |

DN25 |

2050 |

4920 |

|

HBY-22B |

4220 |

3800 |

2240 |

2680 |

1.5*4 |

72800 |

2.2 |

114 |

DN125 |

DN40 |

DN25 |

2100 |

5000 |

|

HBY-22C |

4220 |

3800 |

2240 |

2840 |

1.5*4 |

72800 |

2.2 |

114 |

DN125 |

DN40 |

DN25 |

2150 |

5100 |

|

HBY-22D |

4220 |

3800 |

2240 |

2840 |

1.5*4 |

72800 |

2.2 |

114 |

DN125 |

DN40 |

DN25 |

2250 |

5250 |

|

HBY-22E |

4740 |

4300 |

2240 |

2910 |

1.5*4 |

72800 |

3.7 |

140 |

DN100*2 |

DN40 |

DN25 |

2800 |

6800 |

|

HBY-22F |

5440 |

5000 |

2240 |

2910 |

2.2*4 |

90000 |

3.7 |

140 |

DN100*2 |

DN40 |

DN25 |

3200 |

7820 |

|

HBY-22G |

5440 |

5000 |

2240 |

2910 |

2.2*4 |

90000 |

3.7 |

140 |

DN125*2 |

DN40 |

DN25 |

3300 |

8000 |

|

HBY-26A |

5840 |

5360 |

2600 |

3660 |

4*4 |

240000 |

5.5 |

160 |

DN125*2 |

DN40 |

DN25 |

5000 |

9000 |

|

HBY-26B |

6420 |

5940 |

2600 |

3660 |

4*4 |

240000 |

5.5 |

160 |

DN125*2 |

DN40 |

DN25 |

5500 |

10000 |

|

HBY-29A |

6420 |

5940 |

2900 |

3260 |

4*4 |

240000 |

5.5 |

160 |

DN150*2 |

DN40 |

DN25 |

6500 |

11500 |

|

HBY-29B |

6420 |

5940 |

2900 |

3260 |

4*4 |

240000 |

5.5 |

160 |

DN150*2 |

DN40 |

DN25 |

6800 |

11800 |

|

HBY-29C |

6420 |

5940 |

2900 |

3260 |

4*4 |

240000 |

5.5 |

160 |

DN150*2 |

DN40 |

DN25 |

7000 |

12000 |

Remarks:

1.Design conditions: Inlet temperature t1=37℃, outlet temperature t2=32℃, wet bulb temperature t=28℃, dry bulb temperature O=31.5℃, barometric pressure P=9.94×104Pa;

2.The water tank should ensure that there is enough water, so that the water at the bottom of the tank can be higher than the pump inlet and filter screen when the system is running, and the general water level is > 300mm;

3.The above technical parameters are for reference only. Our company reserves the right to modify the product appearance and technical parameters due to the continuous upgrading of technology.

Related products

Message